SP400-0.009-00-11 Bergquist, SP400-0.009-00-11 Datasheet - Page 6

SP400-0.009-00-11

Manufacturer Part Number

SP400-0.009-00-11

Description

THERMAL PAD TO-3 .009" SP400

Manufacturer

Bergquist

Series

Sil-Pad® 400r

Specifications of SP400-0.009-00-11

Usage

TO-3, TO-66

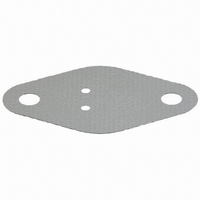

Shape

Rhombus

Outline

33.32mm x 19.35mm

Thickness

0.009" (0.229mm)

Backing, Carrier

Fiberglass

Color

Gray

Thermal Resistivity

1.40°C/W

Thermal Conductivity

0.9 W/m-K

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Adhesive

-

Other names

7403-09FR-11

BER218

BER218

4

Thermal Clad Applications

Power Conversion

Due to the size constraints and watt-density

requirements in DC-DC conversion, Thermal

Clad has become the favored choice.Thermal

Clad is available in a variety of thermal perfor-

mances, is compatible with mechanical fasten-

ers and is highly reliable. It can be used in

almost every form-factor and fabricated in a

wide variety of substrate metals, thicknesses

and copper foil weights.

Motor Drives

Compact high-reliability motor drives built on

Thermal Clad have set the benchmark for

watt-density. Dielectric choices provide the

electrical isolation necessary to meet operat-

ing parameters and safety agency test require-

ments. With the ability to fabricate in a wide

variety of form-factors, implementation into

either compact or integrated motor drives is

realized. The availability of Thermal Clad HT

makes high temperature operation possible.

Heat-Rail And Forming

The use of Thermal Clad in heat-rail applica-

tions has increased significantly and is current-

ly used in automotive, audio, motor control

and power conversion applications. Thermal

Clad offers many advantages including surface

mount assembly, attachment capabilities and

excellent thermal performance. The dielectric

can be selectively removed and the metal can

be formed with three-dimensional features

making Thermal Clad a versatile substrate.

LEDs

In Power LED applications, light output and

long life are directly attributable to how well

the LED’s are managed thermally. Thermal

Clad is an excellent solution for designers.

Because T-Clad is a metal based material, it

can be configured for special shapes, bends

and thicknesses thus allowing the designer to

put LED light engines in virtually any applica-

tion. Mounting Power LED’s on T-Clad assures

the lowest possible operating temperatures

and maximum brightness, color and life.

Solid State Relays/Switches

The implementation of Solid State Relays in

many control applications calls for thermally

efficient, and mechanically robust substrates.

Thermal Clad offers both. The material con-

struction allows mounting configurations not

reasonably possible with ceramic substrates.

New dielectrics meet the high thermal per-

formance expectations and can even out-per-

form existing ceramic based designs.

Want to maximize the lifecycle and

color consistency of your LEDs?

This LED-specific solutions guide addresses

important factors and recommendations for

selecting a thermal management solution

ideal for your LED design.