SP400-0.009-00-11 Bergquist, SP400-0.009-00-11 Datasheet - Page 4

SP400-0.009-00-11

Manufacturer Part Number

SP400-0.009-00-11

Description

THERMAL PAD TO-3 .009" SP400

Manufacturer

Bergquist

Series

Sil-Pad® 400r

Specifications of SP400-0.009-00-11

Usage

TO-3, TO-66

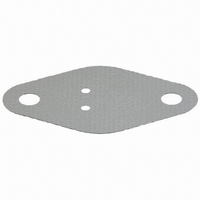

Shape

Rhombus

Outline

33.32mm x 19.35mm

Thickness

0.009" (0.229mm)

Backing, Carrier

Fiberglass

Color

Gray

Thermal Resistivity

1.40°C/W

Thermal Conductivity

0.9 W/m-K

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Adhesive

-

Other names

7403-09FR-11

BER218

BER218

2

Thermal Clad

Key Benefits Of Thermal Clad

The Bergquist Company is the world leader in the develop-

ment and manufacture of thermally conductive interface mate-

rials.Thermal Clad Insulated Metal Substrate (IMS

oped by Bergquist as a thermal management solution for

today’s higher watt-density surface mount applications where

heat issues are a major concern.

Thermal Clad substrates minimize thermal impedance and

conduct heat more effectively and efficiently than standard

printed wiring boards (PWB's). These substrates are more

mechanically robust than thick-film ceramics and direct bond

copper constructions that are often used in these applications.

Thermal Clad is a cost-effective solution which can eliminate

components, allow for simplified designs, smaller devices and an

overall less complicated production processes. Additional ben-

efits of Thermal Clad include lower operating temperatures,

longer component life and increased durability.

Bergquist Thermal Clad substrates are not limited to use with

metal base layers. In one example, power conversion applica-

tions can enhance their performance by replacing FR-4 with

Thermal Clad dielectrics in multi-layer assemblies. In this appli-

cation, the thickness of the copper circuit layer can be mini-

mized by the high thermal performance of Thermal Clad. For

additional information on this topic, refer to the “Specialty

Applications” section on pages 10-11 of this guide.

screws or clamps); a configuration requiring

required use of a large heat sink, interface

material and various hardware (brackets,

Traditionally, cooling an FR-4 board

labor intensive manual assembly.

measured junction temperature

Conventional methods

5W=Tj 43ºC

®

eliminate the need for heat sinks, device

clips, cooling fans and other hardware.

An automated assembly method will

Cooling with Thermal Clad can

®

measured junction temperature

reduce long term costs.

Overview

Thermal Clad

5W=Tj 35ºC

®

) was devel-

Original Power Board Assembly (Actual)

New Power Board Assembly (Actual)

( 66 ) Thru-hole FETs ( 15 ) High profile capacitors ( 9 ) High profile bus bars

Total Weight 3.4 lbs (1543.6 g)

( 48 ) FETs ( 9 ) Low profile capacitors ( 5 ) Low profile bus bars

Total Weight 0.82 lbs (370.6 g)

Thermal Clad is a complete thermal management system, unlike

traditional technology which uses heat sinks, clips and other

mounting hardware. Thermal Clad enables low-cost production

by eliminating the need for costly manual assembly.

Thermal Clad Benefits

• RoHS compliant and halogen-free

• Lower component operating temperatures

• Reduce printed circuit board size

• Increase power density

• Extend the life of dies

• Reduce the number of interconnects

• Improve product thermal and mechanical performance

• Combine power and control

• Improve product durability

• Enable better use of surface mount technology

• Reduce heat sinks and other mounting hardware, including

• Replace fragile ceramic substrates with greater

• Bergquist is your one-stop source from raw materials

thermal interface material

mechanical durability

to finished circuit