SP400-0.009-00-11 Bergquist, SP400-0.009-00-11 Datasheet - Page 8

SP400-0.009-00-11

Manufacturer Part Number

SP400-0.009-00-11

Description

THERMAL PAD TO-3 .009" SP400

Manufacturer

Bergquist

Series

Sil-Pad® 400r

Specifications of SP400-0.009-00-11

Usage

TO-3, TO-66

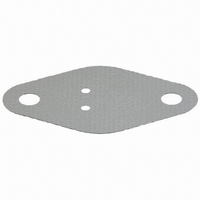

Shape

Rhombus

Outline

33.32mm x 19.35mm

Thickness

0.009" (0.229mm)

Backing, Carrier

Fiberglass

Color

Gray

Thermal Resistivity

1.40°C/W

Thermal Conductivity

0.9 W/m-K

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Adhesive

-

Other names

7403-09FR-11

BER218

BER218

6

Selecting Dielectric Materials

Dielectric Layer

The technology of Thermal Clad resides in the dielectric layer. It is the

key element for optimizing performance in your application.The dielec-

tric is a proprietary polymer/ceramic blend that gives Thermal Clad its

excellent electrical isolation properties and low thermal impedance.

The polymer is chosen for its electrical isolation properties, ability

to resist thermal aging and high bond strengths. The ceramic filler

enhances thermal conductivity and maintains high dielectric strength.

The result is a layer of isolation which can maintain these properties

even at 0.003" (76µm) thickness. See high power lighting applications

for thinner dielectric information. This guide will help you select the

best dielectric to suit your needs for watt-density, electrical isolation

and operating temperature environment.

Standardized Methods For

Measuring Thermal Conductivity

There are several different test methods for determining a material’s

thermal conductivity value. Results can be different depending on the

method chosen, so it is important to use similar test methods in

material comparisons. See chart at right.

Standard test methods include ASTM D5470 and ASTM E1461.

ASTM D5470 is a steady state method and is referred to as the

guarded hot plate. This method provides an analytically derived value

and does not use approximations. ASTM E1461 is a transient method

referred to as Laser Flash Diffusivity. In E1461, thermal diffusivity is the

test output and thermal conductivity is calculated.

Non-Standard In-House Test Methods

The adjacent chart shows how vastly different thermal conductivity

values can be achieved by using “in-house” or non-standard test

methods. For example, when the same dielectric is chosen we can

derive a completely different and much higher thermal conductivity

value by testing a stack-up or laminate with base layer.We can modify

the test further by using different materials for the substrate to obtain

even higher results. Although thermal conductivity values are still rela-

tive to one another so a comparison can be made, these test meth-

ods do not give us an accurate depiction of true thermal perfor-

mance in the application. Included in the chart is a modeled value for

thermal conductivity, a respected model for predicting the effective

thermal conductivity of anisotropic particulate composites, but not

helpful for determining thermal performance in application. We

emphasize using standard test methods such as ASTM D5470 and

ASTM E1461, which are universally accepted and repeatable.

Note: The hot disk method is not a method we use for comparison

because typically this method measures the conductivity of the dielectric

alone, which neglects thermal interfacial resistance between layers and

carrier holding the dielectric. These values must be understood in order to

calculate the actual thermal impedance or thermal performance data.

See section regarding thermal impedance on page 7.

Thermal Conductivity

Thermal conductivity is relevant to the application’s thermal performance

when the thickness of the dielectric material, interfacial resistance and area

are taken into consideration. See “Thermal Impedance” section for more

information, as this data will be the most relevant to your application.

Method

Description

Part

Number

HT-04503

HT-07006

MP-06503

Part

Number

HT-04503

HT-07006

MP-06503

Laminate

Material

Circuit

CML

Test Methods

Model

D5470

ASTM

9.0

9.0

4.5

2.2

2.2

1.3

1 - Bruggeman Model

2 - Tested with 0.062" (1.57mm) 5052 aluminum substrate

3 - Tested with 0.062"(1.57mm) 1100 copper substrate

Standardized

1

Multi-Purpose

1

and 2 oz. (70 µ m) copper foil

and 2 oz. (70 µ m) foil

Non-Standard Thermal Conductivity Test

Hot Plate

Laminate

Guarded

MP

(W/m-K)

32.2

21.5

14.0

E1461

ASTM

Methods and Model

1.97

1.97

1.17

2

2

High Temperature

Laminate

Hot Plate

Guarded

36.4

23.3

24.0

1 - ASTM D5470

2 - ASTM E1461

Method

Description

HT

Guarded Hot Plate

Laser Flash Diffusivity

3

(W/m-K)

Laser Flash

Laminate

67.6

46.0

34.9

High Power

Lighting

2

HPL

Laser Flash

Laminate

86.5

115

102

3