171662-1 TE Connectivity, 171662-1 Datasheet - Page 52

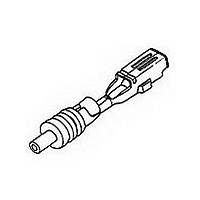

171662-1

Manufacturer Part Number

171662-1

Description

E-J MK-2 070 REC CONT

Manufacturer

TE Connectivity

Type

Contactr

Series

070r

Datasheet

1.171662-1.pdf

(80 pages)

Specifications of 171662-1

Gender

RCP

Body Orientation

Straight

Housing Material

Not Required

Number Of Contacts

1POS

Number Of Ports

1Port

Number Of Terminals

1

Pitch (mm)

Not Requiredmm

Contact Material

Brass

Operating Temp Range

-30C to 105C

Mounting Style

Cable

Termination Method

Crimp

Contact Plating

Pre-Tin

Product Height (mm)

3.6mm

Product Depth (mm)

5.4mm

Product Length (mm)

16.5mm

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

16 – 20

Wire/cable Size (mm²)

0.5 – 1.25

Wire Type

Stranded

Contact Type

Socket

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Pre-Tin

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

2.00 – 2.60 [0.079 – 0.102]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

171662-1

Manufacturer:

TE/AMP

Quantity:

30 000

Company:

Part Number:

171662-1

Manufacturer:

TE/TYCO

Quantity:

6 600

52

AMP Sealed Connectors

A

Performance

Characteristics

Maximum Current Maximum current

rating of Universal MATE-N-LOK

connectors is limited by the maximum

operating temperature of the housings

which is 125°C including the

temperature rise of the contacts which is

a maximum of 30°C. There are several

variables which have a direct effect on

this maximum current-carrying

capability for a given connector and

must be considered for each application.

These variables are:

Wire Size Large diameter wire will

carry more current since it has less

internal resistance to current flow and

thus generates less heat. Longer wire

lengths also enhance current carrying

capabilities since the wire conducts heat

away from the connector

Connector Size In general, the more

circuits in a connector, the less current

can be carried.

Ambient Temperature The higher

the ambient temperature, the less

current can be carried in any given

connector.

Printed Wiring Board Conductor

Size The finished trace conductor

width and thickness should be

maximized to allow for the greatest

current carrying capacity and heat

dissipation.

Universal MATE-N-LOK connectors also

will withstand the following tests:

Vibration 10-55-10 cycles per minute

at .06 inch total excursion

Physical Shock 18 drops, 50 g

sawtooth at 10 milliseconds

Housing Panel Retention 75 lb min.

Housing Lock Strength 30 lb. min.

Thermal Shock -55°C to +85°C

Temperature-Humidity Cycling

25°C to 65°C at 95 RH

Corrosion 48 hr. at 5% salt

concentration

Related Product Data

Product Specifications

106-1031 Universal MATE-N-LOK

108-1053 Universal MATE-N-LOK

Connectors

Headers

(Continued)

AMP Technical Support Center/AMP FAX Service

1-800-522-6752 717-986-7777

AMP Sealed Connectors

Current Rating Verification for 30°C Maximum Temperature Rise 100% Energized

Wire-to-Wire

UMNL Calculated Current Table

Values are based on initial Temperature Rise versus Current Testing and are intended to be a guide in the selection

of a connector family. All applications should be tested by the end user. The values listed are per circuit for fully

loaded housings being 100% energized. Note: All combinations were not tested, and this chart contains interpolated

and extrapolated values.

Wire-to-Board

Due to the vast differences in trace geometry and printed circuit board configurations, we

are unable to provide a separate current carrying chart for our printed circuit board

header products. However, the above Wire-to-Wire charts may be used as a guideline for

headers if the trace width and thickness is equal to the listed wire gauge. For vertical

headers, only 75% of the Wire-to-Wire value should be used. The chart values are only a

tool for connector selection and will require the customer to fully test their application.

Splash Proof/Sealed Universal MATE-N-LOK Connectors

Number of

Circuits

12

15

2

3

4

6

9

Termination Resistance/Contact Crimp Tensile Force

Notes: This is the total resistance between wire crimps of a mated pin and

socket.

Minimum Wire Lengths for T-Rise vs. Current Testing

Notes: If wire lengths used are less than those listed above, the current

carrying ability of the system will be reduced due to less heat being

conducted away from the connector. The customer should fully test all

applications

19.00

17.50

16.50

15.00

13.50

12.50

12.00

AWG

10

24

22

20

18

16

14

Wire Size

AWG

24

20

18

16

14

18.00

16.50

15.50

14.00

12.50

12.00

11.50

mm

12

1.2

2.0

.2

.3

.5

.8

2

17.00

15.50

15.00

13.00

11.50

11.00

10.00

14

Dimensions are in

millimeters over [inches]

Current

(Amps)

Test

1.5

4.5

10

3

6

8

14.50

13.00

12.50

11.00

Termination

9.50

9.00

8.50

Resistance

16

Resistance

(Max. Init.)

Milliohms

13.00

12.00

11.00

9.50

8.50

8.00

7.50

3.50

3.50

3.00

3.00

2.75

2.75

Wire Gauge

18

10.00

7.850

9.00

8.50

6.50

6.00

6.00

Min. Length (in.)

20

287.0 [11.3]

129.5 [5.1]

198.1 [7.8]

238.8 [9.4]

348 [13.7]

www.amp.com

Tensile Force

lbs.

Force (Min.)

14

14

30

45

50

8

8.00

7.50

7.00

6.00

5.50

5.00

4.50

Contact

22

Crimp

133

200

222

(Continued)

36

62

62

6.50

6.00

5.50

5.00

4.50

4.00

4.00

N

24

Specifications

subject to change.

5.50

5.00

4.50

4.00

3.50

3.00

3.00

Revised 01-00

26

Catalog

3.50

3.00

3.00

2.50

2.00

2.00

2.00

65481

30