CYII4SM6600-EVAL Cypress Semiconductor Corp, CYII4SM6600-EVAL Datasheet - Page 32

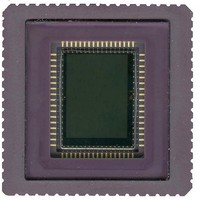

CYII4SM6600-EVAL

Manufacturer Part Number

CYII4SM6600-EVAL

Description

BOARD EVAL IMAGE SENS IBIS4-6600

Manufacturer

Cypress Semiconductor Corp

Datasheet

1.CYII4SC6600-EVAL.pdf

(34 pages)

Specifications of CYII4SM6600-EVAL

Sensor Type

CMOS Imaging, Monochrome

Sensing Range

6.6 Megapixel

Interface

SPI

Sensitivity

89 fps

Voltage - Supply

2.5 V ~ 3.3 V

Embedded

No

Utilized Ic / Part

IBIS4-6600

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Glass Lid Specifications

Monochrome Sensor

A D263 glass is used as protection glass lid on top of the IBIS4-6600 monochrome sensors. The refraction index of the D263 glass

lid is 1.52.

Storage and Handling

Storage Conditions

Table 16. Storage Conditions

Handling and Soldering Conditions

Special care must be taken when soldering image sensors with

color filter arrays (RGB color filters), onto a circuit board,

because color filters are sensitive to high temperatures.

Prolonged heating at elevated temperatures may result in

deterioration of the performance of the sensor. The following

recommendations ensure that sensor performance is not

compromised during end-users assembly processes.

Board Assembly

Device placement onto boards must be done in accordance with

strict ESD controls for Class 0, JESD22 Human Body Model, and

Class A, JESD22 Machine Model devices. Assembly operators

must always wear all designated and approved grounding

equipment.

workstations are recommended, including the use of ionized

blowers. All tools must be ESD protected.

Document Number: 001-02366 Rev. *G

Temperature

Description

Figure 30

Grounded

Minimum

shows the transmission characteristics of the D263 glass.

–30

wrist

100

90

80

70

60

50

40

30

20

10

0

400

Figure 30. Transmittance Curve of the D263 Cover Glass Lid

Maximum

straps

+85

at

500

ESD

Maximum

°C

protected

Wavelength [nm]

600

Manual Soldering

When a soldering iron is used, the following conditions must be

observed:

■

■

Reflow Soldering

Figure 31

thermal profile for a reflow soldering system. If the

temperature/time profile exceeds these recommendations,

damage to the image sensor may occur. See

33 for more details.

Precautions and Cleaning

Avoid spilling solder flux on the cover glass, because bare glass

and particularly glass with antireflection filters may be adversely

affected by the flux. Avoid mechanical or particulate damage to

the cover glass.

It is recommended that isopropyl alcohol (IPA) be used as a

solvent for cleaning the image sensor glass lid. When using other

solvents, it must be confirmed beforehand whether the solvent

can dissolve the package and/or the glass lid.

Use a soldering iron with temperature control at the tip. The

soldering iron tip temperature must not exceed 350°C.

The soldering period for each pin must be less than 5 seconds.

700

on page 33 shows the maximum recommended

IBIS4-6600 CYII4SM6600AB

800

900

Figure 31

Page 32 of 34

on page

[+] Feedback