AT91SAM7X256B-CU Atmel, AT91SAM7X256B-CU Datasheet - Page 507

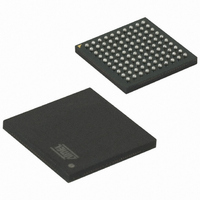

AT91SAM7X256B-CU

Manufacturer Part Number

AT91SAM7X256B-CU

Description

IC MCU 256KB FLASH 100TFBGA

Manufacturer

Atmel

Series

AT91SAMr

Specifications of AT91SAM7X256B-CU

Core Processor

ARM7

Core Size

16/32-Bit

Speed

55MHz

Connectivity

CAN, Ethernet, I²C, SPI, SSC, UART/USART, USB

Peripherals

Brown-out Detect/Reset, DMA, POR, PWM, WDT

Number Of I /o

62

Program Memory Size

256KB (256K x 8)

Program Memory Type

FLASH

Ram Size

64K x 8

Voltage - Supply (vcc/vdd)

1.65 V ~ 1.95 V

Data Converters

A/D 8x10b

Oscillator Type

Internal

Operating Temperature

-40°C ~ 85°C

Package / Case

100-TFBGA

Processor Series

91S

Core

ARM7TDMI

Data Bus Width

32 bit

Data Ram Size

64 KB

Interface Type

CAN, Ethernet, SPI, I2S, TWI, USART, USB

Maximum Clock Frequency

55 MHz

Number Of Programmable I/os

62

Number Of Timers

3

Operating Supply Voltage

3.3 V

Maximum Operating Temperature

+ 85 C

Mounting Style

SMD/SMT

Minimum Operating Temperature

- 40 C

Operating Temperature Range

- 40 C to + 85 C

Package

100TFBGA

Device Core

ARM7TDMI

Family Name

91S

Maximum Speed

55 MHz

On-chip Adc

8-chx10-bit

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Eeprom Size

-

Lead Free Status / Rohs Status

Details

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

- Current page: 507 of 687

- Download datasheet (11Mb)

36.3

36.4

Table 36-1.

36.5

36.5.1

36.5.2

36.5.3

6120H–ATARM–17-Feb-09

Name

CANRX

CANTX

Application Block Diagram

I/O Lines Description

Product Dependencies

I/O Lines

Power Management

Interrupt

I/O Lines Description

Description

CAN Receive Serial Data

CAN Transmit Serial Data

Figure 36-2.

The pins used for interfacing the CAN may be multiplexed with the PIO lines. The programmer

must first program the PIO controller to assign the desired CAN pins to their peripheral function.

If I/O lines of the CAN are not used by the application, they can be used for other purposes by

the PIO Controller.

The programmer must first enable the CAN clock in the Power Management Controller (PMC)

before using the CAN.

A Low-power Mode is defined for the CAN controller: If the application does not require CAN

operations, the CAN clock can be stopped when not needed and be restarted later. Before stop-

ping the clock, the CAN Controller must be in Low-power Mode to complete the current transfer.

After restarting the clock, the application must disable the Low-power Mode of the CAN

controller.

The CAN interrupt line is connected on one of the internal sources of the Advanced Interrupt

Controller. Using the CAN interrupt requires the AIC to be programmed first. Note that it is not

recommended to use the CAN interrupt line in edge-sensitive mode.

Application Block Diagram

CAN-based Application Layer

AT91SAM7X512/256/128 Preliminary

CAN Data Link Layer

CAN-based Profiles

CAN Physical Layer

Layers

Implementation

CAN Controller

Transceiver

Software

Software

Type

Input

Output

507

Related parts for AT91SAM7X256B-CU

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

KIT EVAL FOR AT91SAM7X256/128

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU, MPU & DSP Development Tools KICKSTART KIT ATMEL AT91SAM7X

Manufacturer:

IAR Systems

Part Number:

Description:

MCU ARM9 64K SRAM 144-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM7 MCU FLASH 256K 100LQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MPU 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM9 ULTRA LOW PWR 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM9 324-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC MCU ARM9 SAMPLING 217CBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 208-PQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM 512K HS FLASH 100-LQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM 512K HS FLASH 100-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 200 MHZ 324-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM MCU 16BIT 128K 256BGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM7 MCU 32BIT 128K 64LQFP

Manufacturer:

Atmel

Datasheet: