LC1D18R7 SQUARE D, LC1D18R7 Datasheet - Page 10

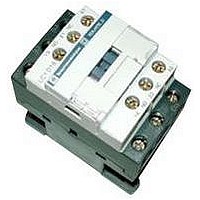

LC1D18R7

Manufacturer Part Number

LC1D18R7

Description

IEC Contactor

Manufacturer

SQUARE D

Datasheet

1.LC1D09BD.pdf

(252 pages)

Specifications of LC1D18R7

No. Of Poles

3

Contact Configuration

3PST-NO

Relay Mounting

DIN Rail

Coil Voltage Vac Nom

440V

Relay Terminals

Screw Clamp

Width

45mm

Coil Resistance

2.24kohm

Nom Operating Power

10kW

External Width

45mm

Operating Voltage

600VAC

Switching Power Ac1

3hp

Switching Power Ac3

15hp

Switching Current Ac1

32A

Switching Current Ac3

18A

Load Current Inductive

18A

Load Current Resistive

32A

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

- Current page: 10 of 252

- Download datasheet (14Mb)

Technical Information: Protective Treatment / Climatic Environment

10

©

2001-2004 Schneider Electric All Rights Reserved

Technical Information: Protective Treatment According to Climatic Environment

Depending on the climatic and environmental conditions in which the equipment is placed,

Telemecanique can offer specially adapted products to meet your requirements.

In order to make the correct choice of protective finish, two points should be remembered:

• The prevailing climate of the country is never the only criterion.

• Only the atmosphere in the immediate vicinity of the equipment should be considered.

“TC” Treatment for All Climates

“TC” is the standard treatment for Telemecanique equipment and is suitable for the vast majority of

applications. It is the equivalent of treatments described as “Klimafest,” “Climateproof,” “Total

Tropicalization,” or “Super Tropicalization,” and meets the following requirements:

• Publication UTE C 63-100 (method l), successive cycles of humid heat at + 40 °C (104 °F) and

• DIN 50016 — Variations of ambient conditions within a climatic chamber:

It also meets the requirements of the marine classification authority BV-LROS-GL-DNV-RINA.

Characteristics

• Steel components are usually treated with zinc chromate and, when they have a mechanical function,

• Insulating materials are selected for their high electrical, dielectric and mechanical characteristics.

• Metal enclosures have a stoved paint finish, applied over a primary phosphate protective coat, or are

Limits for Use of “TC” (All Climates) Treatment

• “TC” treatment is suitable for the following temperatures and humidity:

• It may also be used where the above limits are only exceeded accidentally or for very short periods,

Extension of Use of “TC” (All Climates) Treatment

In cases where the humidity around the equipment exceeds the conditions described above, where the

equipment (in tropical regions) is mounted outdoors, or where it is placed in a very humid location

(laundries, sugar refineries, steam rooms, and so forth), “TC” treatment can still be used if the following

precautions are taken:

• The enclosure in which the equipment is mounted must be protected with a “TH” finish (see page 11)

• Components mounted inside the enclosure must have a “TC” finish.

• If the equipment is to be switched off for long periods, a heater must be provided (0.2 to 0.5 kW per

95% relative humidity.

+ 23 °C (73 °F) and 83% relative humidity,

+ 40 °C (104 °F) and 92% relative humidity.

they may also be painted.

galvanized (for example, some prefabricated busbar trunking components).

or where temperature variations are not sufficient or fast enough to cause heavy condensation or

dripping water on the equipment. “TC” treatment is therefore suitable for all latitudes, including

tropical and equatorial regions, where the equipment is mounted in normal, ventilated industrial

locations. Being sheltered from external climatic conditions, temperature variations are small, the risk

of condensation is minimized, and the risk of dripping water is virtually non-existent.

and must be well ventilated to avoid condensation and dripping water (for example, enclosure base

plate mounted on spacers).

square decimeter / 15.5 square inch of enclosure), switched on automatically when the equipment is

turned off. This heater keeps the inside of the enclosure at a temperature slightly higher than the

outside surrounding temperature, thereby avoiding any risk of condensation and dripping water (the

heat produced by the equipment itself in normal running is sufficient to provide this temperature

difference).

Temperature

Relative Humidity

20 °C (68 °F)

95%

40 °C (104 °F)

80%

50 °C (122 °F)

50%

01/04

Related parts for LC1D18R7

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Pushbutton, Non-Illum'd Red "STOP", Momentary, 1NO-1NC, Square 30mm, 10A, 600V

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

KITS,TWIDO? PROGRAMMABLE CONTROLLERS,KITS,TWIDOPACK STARTER KIT - ADVANCED LEVEL,PROGRAMMABLE CONTROLLERS,TWIDO? PROGRAMMABLE CONTROLLERS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

I/O EXTENDER MODULE 4 D IN & 2 D OUTPUT

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

CB ACCESSORY, UNDERVOLTAGE TRIP 48V DC

Manufacturer:

SQUARE D

Datasheet: