LC1D18R7 SQUARE D, LC1D18R7 Datasheet - Page 11

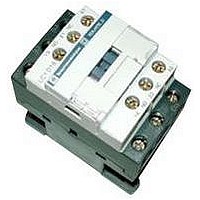

LC1D18R7

Manufacturer Part Number

LC1D18R7

Description

IEC Contactor

Manufacturer

SQUARE D

Datasheet

1.LC1D09BD.pdf

(252 pages)

Specifications of LC1D18R7

No. Of Poles

3

Contact Configuration

3PST-NO

Relay Mounting

DIN Rail

Coil Voltage Vac Nom

440V

Relay Terminals

Screw Clamp

Width

45mm

Coil Resistance

2.24kohm

Nom Operating Power

10kW

External Width

45mm

Operating Voltage

600VAC

Switching Power Ac1

3hp

Switching Power Ac3

15hp

Switching Current Ac1

32A

Switching Current Ac3

18A

Load Current Inductive

18A

Load Current Resistive

32A

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

- Current page: 11 of 252

- Download datasheet (14Mb)

01/04

• For pilot devices, the use of “TC” treatment can be extended to outdoor use provided the enclosure

“TH” Treatment for Hot and Humid Environments

This treatment is for hot and humid atmospheres where installations are subject to condensation,

dripping water, and the risk of fungi.

Plastic insulating components are also resistant to attacks from insects such as termites and

cockroaches. These properties have led to this treatment being described as “Tropical Finish,” but this

does not mean that all equipment installed in tropical and equatorial regions must have undergone “TH”

treatment. On the other hand, certain operating conditions in temperate climates may well require the

use of “TH”-treated equipment (see the Limits for Use of “TC” Treatment section on page 10).

The following are special characteristics of “TH” treatment:

• All insulating components are made of materials which are either resistant to fungi or treated with a

• Metal enclosures receive a top-coat of baked, fungicidal paint, applied over a rust inhibiting

Special Precautions for Electronic Equipment

Electronic products always meet the requirements of “TC” treatment. A number of them are “TH”-treated

as standard.

Some electronic products (for example, programmable controllers, flush-mountable controllers CCX,

and flush-mountable operator terminals XBT) necessitate the use of an enclosure providing a degree of

protection to at least IP 54 (as defined by the standards IEC 60664 and NF C 20 040) for use in industrial

applications or in environmental conditions requiring a “TH” treatment.

These electronic products, including flush-mountable products, must have a degree of protection to at

least IP 20 (either provided by the enclosure itself or following installation) for restricted access locations

where the degree of pollution does not exceed 2 (a test booth not containing machinery or other dust

producing activities, for example).

Protective Treatment Selection Guide

Location

Indoors

Outdoors

(sheltered)

Exposed

outdoors, or

near the sea

These treatments cover, in particular, the applications defined by methods I and II of guide UTE C 63-100.

is made of light alloys, zinc alloys, or plastic material. In this case, it is essential to ensure that the

degree of protection against penetration of liquids and solid objects is suitable for the applications

involved.

fungicide, having increased resistance to creepage (Standards IEC 112, NF C 26-220, DIN 5348).

undercoat. Components with “TH” treatment may be subject to a surcharge (a large number of

Telemecanique products are “TH” treated as standard and are, therefore, not subject to a price

surcharge). Please consult our local representatives or agents.

Environmental

Conditions

No dripping water

or condensation

Presence of

dripping water

or condensation

No dripping water

or dew

Frequent and

regular presence

of dripping water

or dew

Technical Information: Protective Treatment / Climatic Environment

Duty Cycle

Unimportant

Frequent

switching off

for periods of

more than 1 day

Continuous

Unimportant

Frequent

switching off

for periods of

more than 1 day

Continuous

Internal Heating of

Enclosure when

Not in Use

Unnecessary

No

Yes

Unnecessary

Unnecessary

No

Yes

Unnecessary

©

2001-2004 Schneider Electric All Rights Reserved

Type of Climate

Unimportant

Temperate

Equatorial

Unimportant

Unimportant

Temperate

Equatorial

Temperate

Equatorial

Unimportant

Unimportant

Protective Treatment of

Components

“TC”

“TC”

“TH”

“TC”

“TC”

“TC”

“TH”

“TC”

“TH”

“TC”

“TC”

Enclosure

“TC”

“TH”

“TH”

“TH”

“TH”

“TC”

“TH”

“TH”

“TH”

“TH”

“TH”

11

Related parts for LC1D18R7

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Pushbutton, Non-Illum'd Red "STOP", Momentary, 1NO-1NC, Square 30mm, 10A, 600V

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

KITS,TWIDO? PROGRAMMABLE CONTROLLERS,KITS,TWIDOPACK STARTER KIT - ADVANCED LEVEL,PROGRAMMABLE CONTROLLERS,TWIDO? PROGRAMMABLE CONTROLLERS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Part Number:

Description:

LAMPS,INDICATOR,STACKABLE,LAMPS, STACKABLE INDICATOR,VISUAL INDICATING SIGNALS,XVB SERIES INDICATING BANKS ,SQUARE D

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

I/O EXTENDER MODULE 4 D IN & 2 D OUTPUT

Manufacturer:

SQUARE D

Datasheet:

Part Number:

Description:

CB ACCESSORY, UNDERVOLTAGE TRIP 48V DC

Manufacturer:

SQUARE D

Datasheet: