HGTG20N60B3D Fairchild Semiconductor, HGTG20N60B3D Datasheet - Page 6

HGTG20N60B3D

Manufacturer Part Number

HGTG20N60B3D

Description

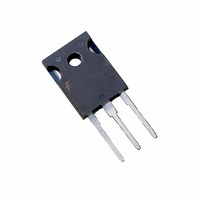

IGBT N-CH UFS 600V 20A TO-247

Manufacturer

Fairchild Semiconductor

Datasheet

1.HGTG20N60B3D.pdf

(7 pages)

Specifications of HGTG20N60B3D

Voltage - Collector Emitter Breakdown (max)

600V

Vce(on) (max) @ Vge, Ic

2V @ 15V, 20A

Current - Collector (ic) (max)

40A

Power - Max

165W

Input Type

Standard

Mounting Type

Through Hole

Package / Case

TO-247-3

Transistor Type

IGBT

Dc Collector Current

40A

Collector Emitter Voltage Vces

2V

Power Dissipation Pd

165W

Collector Emitter Voltage V(br)ceo

600V

Transistor Case Style

TO-247

No. Of Pins

3

Svhc

No SVHC

Rohs Compliant

Yes

Operating Temperature Range

-40°C To +150°C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Igbt Type

-

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

HGTG20N60B3D

Manufacturer:

MITSUBISHI

Quantity:

5 000

Part Number:

HGTG20N60B3D

Manufacturer:

FAIRCHILD/仙童

Quantity:

20 000

Test Circuit and Waveform

Handling Precautions for IGBTs

Insulated Gate Bipolar Transistors are susceptible to

gate-insulation damage by the electrostatic discharge of

energy through the devices. When handling these devices,

care should be exercised to assure that the static charge built

in the handler’s body capacitance is not discharged through

the device. With proper handling and discharge procedures,

however, IGBTs are currently being extensively used in

production by numerous equipment manufacturers in military,

industrial and consumer applications, with virtually no damage

problems due to electrostatic discharge. IGBTs can be

handled safely if the following basic precautions are taken:

©2001 Fairchild Semiconductor Corporation

1. Prior to assembly into a circuit, all leads should be kept

2. When devices are removed by hand from their carriers, the

3. Tips of soldering irons should be grounded.

4. Devices should never be inserted into or removed from

5. Gate Voltage Rating - Never exceed the gate-voltage

6. Gate Termination - The gates of these devices are

7. Gate Protection - These devices do not have an internal

shorted together either by the use of metal shorting

springs or by the insertion into conductive material such

as “ECCOSORBD

hand being used should be grounded by any suitable

means - for example, with a metallic wristband.

circuits with power on.

rating of V

permanent damage to the oxide layer in the gate region.

essentially capacitors. Circuits that leave the gate open-

circuited or floating should be avoided. These conditions

can result in turn-on of the device due to voltage buildup

on the input capacitor due to leakage currents or pickup.

monolithic zener diode from gate to emitter. If gate

protection is required an external zener is recommended.

FIGURE 18. INDUCTIVE SWITCHING TEST CIRCUIT

R

G

= 10

GEM

. Exceeding the rated V

LD26” or equivalent.

L = 100 H

RHRP3060

+

-

GE

V

can result in

DD

= 480V

Operating Frequency Information

Operating frequency information for a typical device (Figure 13)

is presented as a guide for estimating device performance

for a specific application. Other typical frequency vs collector

current (I

for a typical unit in Figures 4, 7, 8, 11 and 12. The operating

frequency plot (Figure 13) of a typical device shows f

f

based on measurements of a typical device and is bounded

by the maximum rated junction temperature.

f

Deadtime (the denominator) has been arbitrarily held to 10%

of the on- state time for a 50% duty factor. Other definitions

are possible. t

Device turn-off delay can establish an additional frequency

limiting condition for an application other than T

is important when controlling output ripple under a lightly

loaded condition.

f

allowable dissipation (P

The sum of device switching and conduction losses must

not exceed P

and the conduction losses (P

P

E

shown in Figure 19. E

power loss (I

integral of the instantaneous power loss during turn-off. All

tail losses are included in the calculation for E

collector current equals zero (I

V

V

MAX2

MAX1

MAX2

I

GE

C

ON

CE

CE

= (V

and E

is defined by f

whichever is smaller at each point. The information is

is defined by f

CE

FIGURE 19. SWITCHING TEST WAVEFORMS

CE

OFF

x I

) plots are possible using the information shown

CE

D

d(OFF)I

CE

t

. A 50% duty factor was used (Figure 13)

d(OFF)I

are defined in the switching waveforms

x V

90%

)/2.

10%

CE

MAX2

MAX1

and t

ON

) during turn-on and E

D

t

fI

) is defined by P

is the integral of the instantaneous

= (P

d(ON)I

= 0.05/(t

E

C

D

OFF

CE

90%

) are approximated by

- P

are defined in Figure 19.

= 0).

C

d(OFF)I

)/(E

E

ON

D

OFF

10%

= (T

t

d(ON)I

t

d(ON)I

HGTG20N60B3D Rev. B

+ E

OFF

JM

t

OFF

rI

JM

ON

- T

is the

).

; i.e. the

. t

). The

C

MAX1

d(OFF)I

)/R

JC

or

.