FAN6961DY Fairchild Semiconductor, FAN6961DY Datasheet - Page 9

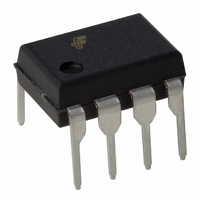

FAN6961DY

Manufacturer Part Number

FAN6961DY

Description

IC PFC CONTROLLER DCM 8DIP

Manufacturer

Fairchild Semiconductor

Datasheet

1.FAN6961SZ.pdf

(13 pages)

Specifications of FAN6961DY

Mode

Discontinuous Conduction (DCM)

Frequency - Switching

60kHz

Current - Startup

10µA

Voltage - Supply

13.5 V ~ 24.5 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Through Hole

Package / Case

8-DIP (0.300", 7.62mm)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

© 2009 Fairchild Semiconductor Corporation

FAN6961 • Rev. 1.0.3

Functional Description

Error Amplifier

The inverting input of the error amplifier is referenced to

INV. The output of the error amplifier is referenced to

COMP. The non-inverting input is internally connected

to a fixed 2.5V ± 2% voltage. The output of the error

amplifier is used to determine the on-time of the PWM

output and regulate the output voltage. To achieve a

low input current THD, the variation of the on time

within one input AC cycle should be very small. A multi-

vector error amplifier is built in to provide fast transient

response and precise output voltage clamping.

For FAN6961, connecting a capacitance, such as 1µF,

between COMP and GND is suggested. The error

amplifier is a trans-conductance amplifier that converts

voltage to current with a 125µmho.

Startup Current

Typical startup current is less than 20µA. This ultra-low

startup current allows the usage of high resistance,

low-wattage startup resistor. For example, 1MΩ/0.25W

startup resistor and a 10µF/25V (V

are recommended for an AC-to-DC power adaptor with

a wide input range 85-265V

Operating Current

Operating current is typically 4.5mA. The low operating

current enables a better efficiency and reduces the

requirement of V

Maximum On-Time Operation

Given a fixed inductor value and maximum output

power, the relationship between on-time and line

voltage is:

If the line voltage is too low or the inductor value is too

high, t

frequency and achieve brownout protection, the

maximum value of t

R

R

The range of the maximum on-time is designed as 10 ~

50µs.

Peak Current Limiting

The switch current is sensed by one resistor. The

signal is feed into CS pin and an input terminal of a

comparator. A high voltage in CS pin terminates a

switching cycle immediately and cycle-by-cycle current

limit is achieved. The designed threshold of the

protection point is 0.82V.

t

t

I

I

on

on

, connected between MOT and GND. A 24kΩ resistor

generates corresponds to 25µs maximum on time:

(max)

=

V

2

ON

rms

•

=

L

2

is too long. To avoid extra low operating

R

•

•

P

I

(

η

o

k

Ω

CC

)

•

hold-up capacitance.

ON

25

24

is programmable by one resistor,

( )

μ

s

AC

.

CC

hold-up) capacitor

(1)

(2)

9

Leading-Edge Blanking (LEB)

A turn-on spike on CS pin appears when the power

MOSFET is switched on. At the beginning of each

switching pulse, the current-limit comparator is disabled

for around 400ns to avoid premature termination. The

gate drive output cannot be switched off during the

blanking period. Conventional RC filtering is not

necessary, so the propagation delay of current limit

protection can be minimized.

Under-Voltage Lockout (UVLO)

The turn-on and turn-off threshold voltage is fixed

internally at

guarantees a one-shot startup with proper startup

resistor and hold-up capacitor. With an ultra-low startup

current of 20µA, one 1MΩ R

under low input line voltage, 85V

on R

(V

Output Driver

With low on resistance and high current driving

capability, the output driver can drive an external

capacitive load larger than 3000pF. Cross conduction

current has been avoided to minimize heat dissipation,

improving efficiency and reliability. This output driver is

internally clamped by a 16.5V Zener diode.

Zero-Current Detection (ZCD)

The zero-current detection of the inductor is achieved

using its auxiliary winding. When the stored energy of

the inductor is fully released to output, the voltage on

ZCD goes down and a new switching cycle is enabled

after a ZCD trigger. The power MOSFET is always

turned on with zero inductor current such that turn-on

loss and noise can be minimized. The converter works

in boundary-mode and peak inductor current is always

exactly twice of the average current. A natural power

factor correction function is achieved with the low-

bandwidth, on-time modulation. An inherent maximum

off time is built in to ensure proper start-up operation.

This ZCD pin can be used as a synchronous input.

Noise Immunity

Noise on the current sense or control signal can cause

significant

boundary-mode operation. Slope compensation and

built-in debounce circuit can alleviate this problem.

Because the FAN6961 has a single ground pin, high

sink current at the output cannot be returned

separately. Good high-frequency or RF layout practices

should be followed. Avoiding long PCB traces and

component leads, locating compensation and filter

components near to the FAN6961, and increasing the

power MOSFET gate resistance improve performance.

AC

=265V

IN

would be less than 0.1W even under high line

rms

pulse-width

) condition.

12V/9.5V.

jitter,

This

IN

is sufficient for startup

rms

hysteresis behavior

particularly

. Power dissipation

www.fairchildsemi.com

in

the