Z0840004PSC Zilog, Z0840004PSC Datasheet - Page 36

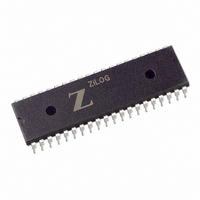

Z0840004PSC

Manufacturer Part Number

Z0840004PSC

Description

IC 4MHZ Z80 NMOS CPU 40-DIP

Manufacturer

Zilog

Datasheet

1.Z0840004PSC.pdf

(98 pages)

Specifications of Z0840004PSC

Processor Type

Z80

Features

NMOS

Speed

4MHz

Voltage

5V

Mounting Type

Through Hole

Package / Case

40-DIP (0.620", 15.75mm)

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

Z0840004PSC

Manufacturer:

ZILOG

Quantity:

2 000

Part Number:

Z0840004PSC

Manufacturer:

ZILOG

Quantity:

20 000

Part Number:

Z0840004PSC (Z80CPU)

Manufacturer:

ZILOG

Quantity:

20 000

Part Number:

Z0840004PSC(Z80CPU)

Manufacturer:

ZILOG

Quantity:

20 000

ZiLOG

2002 Quality and Reliability Report

ZiLOG’S RELIABILITY SUMMARY

ZiLOG’s reliability program is unique, in that the reliability testing takes place on standard

production material at the point of assembly. Reliability testing has been integrated into the

manufacturing process. This flow creates a “Quick Reaction” reliability monitor, and allows

ZiLOG to ensure the integrity of material prior to shipment, gather trend analysis data for internal

corrective actions, and maintain a meaningful database for customer review.

The tests currently employed under ZiLOG’s quick reaction reliability monitor, include early life

(burn-in), steam pressure pot, and temperature cycle. Testing conditions are included with the

attached test results.

In addition to early life testing, a long-term life test is performed on selected lots to gather FIT data.

Test conditions and FIT calculations are included with the attached data. Following are brief

descriptions of various reliability tests included in this program:

EARLY LIFE

Early Life testing, also called burn-in, is typically performed at 125°C for 168 hours. A dynamic or

static bias is employed, depending on the device that is being tested. Early Life test results expose

process or assembly defects. These results are a valuable measure of a given fabrication or

assembly process.

LONG TERM LIFE

Long Term Life testing is generally performed at 150°C for 184 hours. Either dynamic or static

bias is used to stress the device appropriately. These test results are used to estimate field operation

lifetime for a device. This data can be applied to all products manufactured using the same

fabrication process.

PRESSURE POT

Pressure pot testing is performed at 121°C, 15 PSIG, and 100% relative humidity. This test

evaluates the ability of a plastic device to withstand the long-term effects of a humid environment.

TEMPERATURE CYCLE

Temperature Cycle testing is performed at a –65°C to 150°C temperature. This test uses an air-to-

air environment. The 215°C cold to hot temperature difference determines if proper thermal

expansion matching exists between all materials used in device manufacture. The temperature

cycle simulates the thermal stresses a device undergoes during power-up and power-down events.

ZAC03-0004

4 - 5