Z0840004PSC Zilog, Z0840004PSC Datasheet - Page 9

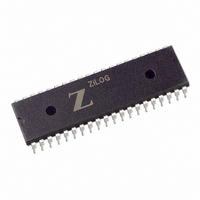

Z0840004PSC

Manufacturer Part Number

Z0840004PSC

Description

IC 4MHZ Z80 NMOS CPU 40-DIP

Manufacturer

Zilog

Datasheet

1.Z0840004PSC.pdf

(98 pages)

Specifications of Z0840004PSC

Processor Type

Z80

Features

NMOS

Speed

4MHz

Voltage

5V

Mounting Type

Through Hole

Package / Case

40-DIP (0.620", 15.75mm)

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

Z0840004PSC

Manufacturer:

ZILOG

Quantity:

2 000

Part Number:

Z0840004PSC

Manufacturer:

ZILOG

Quantity:

20 000

Part Number:

Z0840004PSC (Z80CPU)

Manufacturer:

ZILOG

Quantity:

20 000

Part Number:

Z0840004PSC(Z80CPU)

Manufacturer:

ZILOG

Quantity:

20 000

ZiLOG

2002Quality and Reliability Report

Order Acknowledgment Policy

One definition of vendor quality performance is that the vendor “does what he promises or

acknowledges.” Acceptable reliability and quality is achieved only if ZiLOG and the customer

are in agreement on product and delivery specifications.

Test Guardbanding

No physical attribute is absolute. Customers’ test methods may differ from ZiLOG’s due to

variations in test equipment, temperature or specification interpretation. To ensure that every

ZiLOG product performs to full customer expectations, ZiLOG uses a “waterfall” methodology

in its testing. The first electrical tests made on the circuit for both AC and DC parameters, at the

wafer probe operation, are guardbanded to the final test specifications. The final test

specifications for both AC and DC parameters, in turn, are guardbanded to the quality control

outgoing sample. The quality control outgoing sample is guardbanded to data sheet

specifications. This technique of “waterfall” guardbanding eliminates circuits which may be

marginal to the customer’s expectations long before they get to the shipping container.

Probe at Temperature

Semiconductor devices tend to exhibit their most limited performance at the highest operating

temperature. Therefore, it is ZiLOG’s policy that all chips are tested at high temperature the

very first time they are electrically screened at the wafer probe station. The circuits are tested

again at their upper operating temperature limit in the 100% final test operation.

Process Characterization

Before release to production, every process is thoroughly characterized by an exhaustive series

of pilot production runs and tests which identify the statistical, electrical, and mechanical limits

of that particular process. This documentation is maintained as the historical record or

“footprint” for that particular regime.

Process recharacterization is done any time there is a major process or manufacturing site

change, and the resulting documentation is then added to the characterization history. Once the

process is fully characterized, test site evaluation and process template data is gathered

frequently to make sure that the process remains in specification.

ZAC03-0004

1 - 4