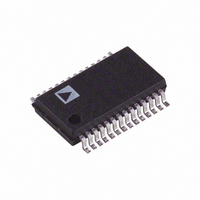

AD1871YRS Analog Devices Inc, AD1871YRS Datasheet - Page 26

AD1871YRS

Manufacturer Part Number

AD1871YRS

Description

IC ADC STEREO AUDIO 24BIT 28SSOP

Manufacturer

Analog Devices Inc

Datasheet

1.AD1871YRSZ.pdf

(28 pages)

Specifications of AD1871YRS

Rohs Status

RoHS non-compliant

Number Of Bits

24

Sampling Rate (per Second)

96k

Data Interface

Serial, SPI™

Number Of Converters

2

Voltage Supply Source

Analog and Digital

Operating Temperature

-40°C ~ 105°C

Mounting Type

Surface Mount

Package / Case

28-SSOP (0.200", 5.30mm Width)

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

AD1871YRS

Manufacturer:

AD

Quantity:

5 510

Company:

Part Number:

AD1871YRS

Manufacturer:

PHILIPS

Quantity:

5 510

Company:

Part Number:

AD1871YRSZ

Manufacturer:

AD

Quantity:

114

Part Number:

AD1871YRSZ

Manufacturer:

ADI/亚德诺

Quantity:

20 000

AD1871

LAYOUT CONSIDERATIONS

In order to operate the AD1871 at its specified performance level,

careful consideration must be given to the layout of the AD1871

and its ancillary circuits. Since the analog inputs to the AD1871

are differential, the voltages in the analog modulator are common-

mode voltages. The excellent common-mode rejection of the part

will remove common-mode noise on these inputs. The analog

and digital supplies of the AD1871 are independent and sepa-

rately pinned out to minimize coupling between the analog and

digital sections of the device. The digital filters will provide

rejection of broadband noise on the power supplies, except at

integer multiples of the modulator sampling frequency. The

digital filters also remove noise from the analog inputs provided

the noise source does not saturate the analog modulator.

However, because the resolution of the AD1871’s ADC is high,

and the noise levels from the AD1871 are so low, care must be

taken with regard to grounding and layout.

The printed circuit board that houses the AD1871 should be

designed so the analog and digital sections are separated and

confined to certain sections of the board. The AD1871 pin

selection has been configured such that its analog and digital

interfaces are connected on opposite ends of the package. This

facilitates the use of ground planes that can be easily separated.

A minimum etch technique is generally best for ground planes

as it gives the best shielding. Figure 26 is a view of the ground

plane separation (between analog and digital) in the area

surrounding the AD1871, taken from the layout of the AD1871

Evaluation Board (EVAL-AD1871EB).

*In the above figure, the black area represents the solder side of the layout. The

silkscreen in white is included for clarity.

Digital and analog ground planes should be joined in only one

place. If this connection is close to the device, it is recom-

mended to use a short (0 W resistor) or ferrite bead inductor as

shown in Figure 27. The pads for the ferrite are positioned on

the solder side directly underneath the AD1871 device.

Avoid running digital lines under the device as they may couple

noise onto the die. The analog ground plane should be allowed

to run under the AD1871 to avoid noise coupling. If it is not

possible to use a power supply plane, the power supply lines to

the AD1871 should use as large a trace as possible to provide

low impedance paths and reduce the effects of glitches on the

power supply lines. Fast switching signals, such as clocks, should

be shielded with digital ground to avoid radiating noise to other

sections of the board, and clock signals should never be run near

Figure 26. Ground Layout

–26–

the analog inputs. Traces on opposite sides of the board should

run at right angles to each other. This will reduce the effects of

feedthrough through the board. A microstrip technique is by far

the best but is not always possible with a double-sided board. In

this technique, the component side of the board is dedicated to

the ground planes while the signals are placed on the other side.

Good decoupling is important when using high speed devices.

All analog and digital supplies should be decoupled to AGND

and DGND, respectively, with 0.1 mF ceramic capacitors in

parallel with 10 mF tantalum capacitors. To achieve the best

from these decoupling capacitors, they should be placed as close

as possible to the device, ideally right up against it, as shown in

Figure 28. In systems where a common supply voltage is used to

drive both the AVDD and DVDD of the AD1871, it is recom-

mended that the system’s AVDD supply be used. This supply

should have the recommended analog supply decoupling between

the AVDD pins of the AD1871 and AGND and the recommended

digital supply decoupling capacitors between the DVDD pin

and DGND.

Another important consideration is the selection of components

such as capacitors, resistors, and operational amplifiers for

the ancillary circuits. The capacitors that are used should in the

analog audio signal chain should be of NPO dielectric (if ceramic)

or metal film. Figure 28 shows the placement of the CAPxx pin

capacitors relative to the CAPxx pins. The placement is intended

to keep the tracking between the capacitor and the pin as short as

possible while also ensuring that the track length from CAPxP

pin to its capacitor equals that of the CAPxN to its capacitor.

Figure 27. Connecting Analog and Digital Grounds

Figure 28. AD1871 Power Supply Decoupling

REV. 0