TLP181 Toshiba, TLP181 Datasheet - Page 57

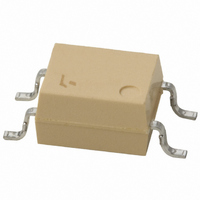

TLP181

Manufacturer Part Number

TLP181

Description

PHOTOCOUPLER TRANS-OUT 4-SMD

Manufacturer

Toshiba

Specifications of TLP181

Number Of Channels

1

Input Type

DC

Voltage - Isolation

3750Vrms

Current Transfer Ratio (min)

50% @ 5mA

Current Transfer Ratio (max)

600% @ 5mA

Voltage - Output

80V

Current - Output / Channel

50mA

Current - Dc Forward (if)

50mA

Vce Saturation (max)

400mV

Output Type

Transistor

Mounting Type

Surface Mount

Package / Case

4-SMD

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

TLP181

Manufacturer:

TOSHIBA

Quantity:

1 500

Company:

Part Number:

TLP181

Manufacturer:

TOSHIBA

Quantity:

184

Part Number:

TLP181

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Part Number:

TLP181 GR

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Part Number:

TLP181(BL

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Part Number:

TLP181(BL-TPL

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Part Number:

TLP181(BL-TPL)

Manufacturer:

TOSHIBA/东芝

Quantity:

20 000

Company:

Part Number:

TLP181(F)

Manufacturer:

TOSHIBA

Quantity:

1 467

Company:

Part Number:

TLP181(GB-TPL

Manufacturer:

TOS

Quantity:

6 022

When using a soldering iron or medium infrared ray/hot air reflow,

avoid a rise in device temperature as much as possible by

observing the following conditions.

1.1 )

1.2 )

1.3 )

2

1. Soldering

a. Solder once within 10 seconds for a lead temperature of

b. Solder once within 3 seconds for a lead temperature of up

a. Complete the infrared ray/hot air reflow process at once

d. Precautions for heating

Using a soldering iron

Using medium infrared ray/hot air reflow

b. Example of temperature profile of lead (Pb) solder

c. Example of temperature profile of lead (Pb)-free solder

The thermal shock of dip soldering increases thermal stress

on devices. To avoid stress, the use of a soldering iron or

medium infrared ray/hot air reflow is recommended. If you

want to use dip soldering, contact your nearest Toshiba

sales representative.

Dip soldering (flow soldering)

up to 260°C.

to 350°C.

within 30 seconds at a package surface temperature

between 210°C and 240°C.

The profile below shows only the typical temperature profile

and conditions, which might not apply to all Toshiba

photocouplers. Temperature profiles and conditions may

differ from product to product. Refer to the relevant technical

datasheets and databooks when mounting a device.

Keeping packages at high temperature for a long period of

time can degrade the quality and reliability of devices.

Soldering time has to be kept as short as possible to

avoid a rise in package temperature.

When using a halogen lamp or infrared heater, avoid

direct irradiation of packages, since this may cause a rise

in package temperature.

Board Assembly Considerations

Example of temperature profile of lead (Pb)-free solder

Example of temperature profile of lead (Pb) solder

(°C)

(°C)

260

230

190

180

240

210

150

60 to 120 seconds

60 to 90 seconds

30 seconds or less

30 to 50 seconds

Time

Time

57

●When cleaning circuit boards to remove flux, make sure that

●Washing devices with water will not cause any problems.

●Do not rub device markings with a brush or with your hand

●Dip cleaning, shower cleaning and steam cleaning processes

●If a device package allows ultrasonic cleaning, keep the

■ The following ultrasonic cleaning conditions

are recommended.

Examples of Alternative Cleaning Agents

Frequency: 27 kHz to 29 kHz

Ultrasonic output power: 300 W or less (0.25 W/cm

Cleaning time: 30 seconds or less

Suspend the circuit board in the solvent bath during ultrasonic

cleaning in such a way that the ultrasonic vibrator does not come

into direct contact with the circuit board or the device.

Conventional cleaning solvents that contain freon are not

recommended due to its adverse effection the earth’s ozone layer.

Alternative freon-free products are available on the market. Some

of these alternative cleaning agents are listed in the table below.

Contact Toshiba or a Toshiba distributor regarding cleaning

conditions and other relevant information for each product type.

no residual reactive ions such as sodium(Na

ions remain. Note that organic solvents react with water to

generate hydrogen chloride and other corrosive gases, which

can degrade device performance.

However, make sure that no reactive ions such as

sodium(Na

sure to dry devices sufficiently after washing.

during cleaning or while the devices are still wet from the

cleaning agent. Doing so can rub off the markings.

all involve the chemical action of a solvent. Use only

recommended solvents for these cleaning methods. When

immersing devices in a solvent or steam bath, make sure

that the temperature of the liquid is 50°C or below and that

the circuit board is removed from the bath within one minute.

duration of ultrasonic cleaning as short as possible, since

long hours of ultrasonic cleaning degrade the adhesion

between the mold resin and the frame material.

2. Flux Cleaning

Technocare

Asahi Clean

Clean Through

Pine Alpha

+

) or chloride(Cl

FRW-1, FRW-17,

FRV-100

AK-225AES

750H

ST-100S,

ST-100SX

–

) ions are left as residue. Also, be

GE Toshiba Silicon

Asahi Glass Co., Ltd

Kao Co., Ltd.

Arakawa Chemical Co., Ltd.

+

) or chloride(Cl

2

or less)

–

)