DEMO9S08LC60 Freescale Semiconductor, DEMO9S08LC60 Datasheet - Page 138

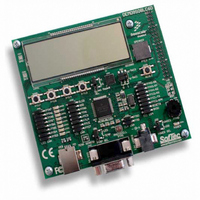

DEMO9S08LC60

Manufacturer Part Number

DEMO9S08LC60

Description

BOARD DEMO FOR 9S08LC60

Manufacturer

Freescale Semiconductor

Type

MCUr

Datasheets

1.DEMO9S08LC60.pdf

(360 pages)

2.DEMO9S08LC60.pdf

(32 pages)

3.DEMO9S08LC60.pdf

(2 pages)

Specifications of DEMO9S08LC60

Contents

Evaluation Board

Processor To Be Evaluated

MC9S08LC60

Interface Type

RS-232, USB

Silicon Manufacturer

Freescale

Core Architecture

HCS08

Core Sub-architecture

HCS08

Silicon Core Number

MC9S08

Silicon Family Name

S08LC

Rohs Compliant

Yes

For Use With/related Products

MC9S08LC60

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

- Current page: 138 of 360

- Download datasheet (4Mb)

Chapter 9 Liquid Crystal Display Driver (S08LCDV1)

9.4.1

The LCD module driver has three modes of operation:

Note all modes are 1/3 bias. These modes of operation are described in more detail in the following

sections.

9.4.1.1

The duty cycle indicates the number of LCD panel segments capable of being driven by each individual

frontplane output driver. Depending on the duty cycle, the LCD waveform drive can be categorized as

either static or multiplex.

In static driving method, the LCD is driven with two square waveforms. The static driving method is the

most basic method to drive an LCD panel, but, because each frontplace driver can drive only one LCD

segment, static driving limits the number of LCD segments that can be driven. In static mode, only one

backplane is required.

In multiplex mode, the LCD waveforms are multi-level and depend on the bias mode. Multiplex mode,

depending on the number of backplanes, can drive multiple LCD segments with a single frontplane driver.

Multiplex mode is effective in reducing the number of driver circuits and the number of connections to

LCD segments. For multiplex mode operation, at least two backplane drivers are needed. The LCD module

is optimized for multiplex mode.

The duty cycle indicates the amount of time the LCD panel segment is energized during each LCD module

frame cycle. The denominator of the duty cycle indicates the number of backplanes that are being used to

drive an LCD panel. Therefore, the available duty cycle options for the LCD module are 1/2, 1/3, and 1/4.

The duty cycle is configured using the DUTY[1:0] bit field in the LCDCR0 register as shown in

Table

138

•

•

•

9-13.

1/2 duty (2 backplanes), 1/3 bias (4 voltage levels)

1/3 duty (3 backplanes), 1/3 bias (4 voltage levels)

1/4 duty (4 backplanes), 1/3 bias (4 voltage levels)

LCD Driver Description

LCD Duty Cycle

Reserved

Duty

1/2

1/3

1/4

MC9S08LC60 Series Data Sheet: Technical Data, Rev. 4

Table 9-13. LCD Module Duty Cycle Modes

DUTY1

LCDCR0 Register

0

1

1

0

DUTY0

1

0

1

0

OFF

OFF

BP3

BP3

N/A

BP2

OFF

BP2

BP2

N/A

Backplanes

BP1

BP1

BP1

BP1

N/A

BP0

BP0

BP0

BP0

N/A

Freescale Semiconductor

Related parts for DEMO9S08LC60

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet:

Part Number:

Description:

Manufacturer:

Freescale Semiconductor, Inc

Datasheet: