AT91SAM7S128C-MU Atmel, AT91SAM7S128C-MU Datasheet - Page 244

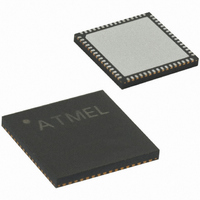

AT91SAM7S128C-MU

Manufacturer Part Number

AT91SAM7S128C-MU

Description

IC MCU ARM7 128K FLASH 64-QFN

Manufacturer

Atmel

Series

AT91SAMr

Specifications of AT91SAM7S128C-MU

Core Processor

ARM7

Core Size

16/32-Bit

Speed

55MHz

Connectivity

I²C, SPI, SSC, UART/USART, USB

Peripherals

Brown-out Detect/Reset, DMA, POR, PWM, WDT

Number Of I /o

32

Program Memory Size

128KB (128K x 8)

Program Memory Type

FLASH

Ram Size

32K x 8

Voltage - Supply (vcc/vdd)

1.65 V ~ 1.95 V

Data Converters

A/D 8x10b

Oscillator Type

Internal

Operating Temperature

-40°C ~ 85°C

Package / Case

64-VQFN Exposed Pad, 64-HVQFN, 64-SQFN, 64-DHVQFN

Core

ARM7TDMI

For Use With

AT91SAM-ICE - EMULATOR FOR AT91 ARM7/ARM9AT91SAM7S-EK - KIT EVAL FOR ARM AT91SAM7S

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Eeprom Size

-

Lead Free Status / Rohs Status

Details

Other names

AT91SAM7S128-MU

AT91SAM7S128-MU

AT91SAM7S128-MU

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

AT91SAM7S128C-MU

Manufacturer:

ATMEL

Quantity:

670

- Current page: 244 of 779

- Download datasheet (11Mb)

27.4.5

27.4.6

27.4.7

244

AT91SAM7S Series Preliminary

Synchronous Data Output

Multi Drive Control (Open Drain)

Output Line Timings

The results of these write operations are detected in PIO_OSR (Output Status Register). When

a bit in this register is at 0, the corresponding I/O line is used as an input only. When the bit is at

1, the corresponding I/O line is driven by the PIO controller.

The level driven on an I/O line can be determined by writing in PIO_SODR (Set Output Data

Register) and PIO_CODR (Clear Output Data Register). These write operations respectively set

and clear PIO_ODSR (Output Data Status Register), which represents the data driven on the I/O

lines. Writing in PIO_OER and PIO_ODR manages PIO_OSR whether the pin is configured to

be controlled by the PIO controller or assigned to a peripheral function. This enables configura-

tion of the I/O line prior to setting it to be managed by the PIO Controller.

Similarly, writing in PIO_SODR and PIO_CODR effects PIO_ODSR. This is important as it

defines the first level driven on the I/O line.

Controlling all parallel busses using several PIOs requires two successive write operations in the

PIO_SODR and PIO_CODR registers. This may lead to unexpected transient values. The PIO

controller offers a direct control of PIO outputs by single write access to PIO_ODSR (Output

Data Status Register). Only bits unmasked by PIO_OWSR (Output Write Status Register) are

written. The mask bits in the PIO_OWSR are set by writing to PIO_OWER (Output Write Enable

Register) and cleared by writing to PIO_OWDR (Output Write Disable Register).

After reset, the synchronous data output is disabled on all the I/O lines as PIO_OWSR resets at

0x0.

Each I/O can be independently programmed in Open Drain by using the Multi Drive feature. This

feature permits several drivers to be connected on the I/O line which is driven low only by each

device. An external pull-up resistor (or enabling of the internal one) is generally required to guar-

antee a high level on the line.

The Multi Drive feature is controlled by PIO_MDER (Multi-driver Enable Register) and

PIO_MDDR (Multi-driver Disable Register). The Multi Drive can be selected whether the I/O line

is controlled by the PIO controller or assigned to a peripheral function. PIO_MDSR (Multi-driver

Status Register) indicates the pins that are configured to support external drivers.

After reset, the Multi Drive feature is disabled on all pins, i.e. PIO_MDSR resets at value 0x0.

Figure 27-4

directly writing PIO_ODSR. This last case is valid only if the corresponding bit in PIO_OWSR is

set.

Figure 27-4

shows how the outputs are driven either by writing PIO_SODR or PIO_CODR, or by

also shows when the feedback in PIO_PDSR is available.

6175K–ATARM–30-Aug-10

Related parts for AT91SAM7S128C-MU

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

KIT EVAL FOR ARM AT91SAM7S

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU, MPU & DSP Development Tools KICKSTART KIT ATMEL AT91SAM7S

Manufacturer:

IAR Systems

Part Number:

Description:

MCU ARM9 64K SRAM 144-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM7 MCU FLASH 256K 100LQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MPU 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM9 ULTRA LOW PWR 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM9 324-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC MCU ARM9 SAMPLING 217CBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 217-LFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 208-PQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM 512K HS FLASH 100-LQFP

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

MCU ARM 512K HS FLASH 100-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM9 MCU 200 MHZ 324-TFBGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM MCU 16BIT 128K 256BGA

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

IC ARM7 MCU 32BIT 128K 64LQFP

Manufacturer:

Atmel

Datasheet: