EP3C25F324I7 Altera, EP3C25F324I7 Datasheet - Page 121

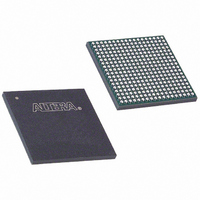

EP3C25F324I7

Manufacturer Part Number

EP3C25F324I7

Description

IC CYCLONE III FPGA 25K 324 FBGA

Manufacturer

Altera

Series

Cyclone® IIIr

Datasheets

1.EP3C5F256C8N.pdf

(5 pages)

2.EP3C5F256C8N.pdf

(34 pages)

3.EP3C5F256C8N.pdf

(66 pages)

4.EP3C5F256C8N.pdf

(14 pages)

5.EP3C5F256C8N.pdf

(76 pages)

6.EP3C25F324I7.pdf

(274 pages)

Specifications of EP3C25F324I7

Number Of Logic Elements/cells

24624

Number Of Labs/clbs

1539

Total Ram Bits

608256

Number Of I /o

215

Voltage - Supply

1.15 V ~ 1.25 V

Mounting Type

Surface Mount

Operating Temperature

-40°C ~ 100°C

Package / Case

324-FBGA

Family Name

Cyclone III

Number Of Logic Blocks/elements

24624

# I/os (max)

215

Frequency (max)

437.5MHz

Process Technology

65nm

Operating Supply Voltage (typ)

1.2V

Logic Cells

24624

Ram Bits

608256

Operating Supply Voltage (min)

1.15V

Operating Supply Voltage (max)

1.25V

Operating Temp Range

-40C to 100C

Operating Temperature Classification

Industrial

Mounting

Surface Mount

Pin Count

324

Package Type

FBGA

For Use With

544-2370 - KIT STARTER CYCLONE III EP3C25

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Number Of Gates

-

Lead Free Status / Rohs Status

Not Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

EP3C25F324I7N

Manufacturer:

ALTERA32

Quantity:

181

Chapter 6: I/O Features in the Cyclone III Device Family

Pad Placement and DC Guidelines

Pad Placement and DC Guidelines

Pad Placement

DC Guidelines

Chapter Revision History

Table 6–7. Chapter Revision History (Part 1 of 3)

© December 2009

December 2009

July 2009

June 2009

October 2008

Date

f

Altera Corporation

Altera recommends that you create a Quartus II design, enter your device I/O

assignments, and compile your design to validate your pin placement. The Quartus II

software checks your pin connections with respect to the I/O assignment and

placement rules to ensure proper device operation. These rules are dependent on

device density, package, I/O assignments, voltage assignments, and other factors that

are not fully described in this chapter.

For more information about how the Quartus II software checks I/O restrictions, refer

to the

For the Quartus II software to automatically check for illegally placed pads according

to the DC guidelines, set the DC current sink or source value to Electromigration

Current assignment on each of the output pins that are connected to the external

resistive load.

The programmable current strength setting has an impact on the amount of DC

current that an output pin can source or sink. Determine if the current strength setting

is sufficient for the external resistive load condition on the output pin.

Table 6–7

Version

3.2

3.1

3.0

2.1

I/O Management

lists the revision history for this chapter.

Minor changes to the text.

Made minor correction to the part number.

Updated to include Cyclone III LS information

■

■

■

■

■

■

■

■

■

Updated chapter part number.

Updated “Introduction” on page 6–1, “PCI-Clamp Diode” on page 6–6, “On-

Chip Series Termination Without Calibration” on page 6–10, “I/O Standards”

on page 6–11, “I/O Banks” on page 6–16, “High-Speed Differential

Interfaces” on page 6–20, and “External Memory Interfacing” on page 6–20.

Updated Table 6–6 on page 6–18.

Added (Note 6) to Table 6–5.

Updated the “I/O Banks” section.

Updated the “Differential Pad Placement Guidelines” section.

Updated the “V

Removed any mention of “RSDS and PPDS are registered trademarks of

National Semiconductor” from chapter.

Updated chapter to new template.

chapter in volume 2 of the Quartus II Handbook.

REF

Pad Placement Guidelines” section.

Changes Made

Cyclone III Device Handbook, Volume 1

6–21