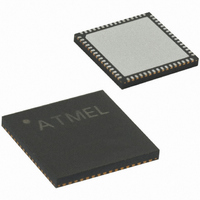

ATXMEGA256A3B-MH Atmel, ATXMEGA256A3B-MH Datasheet - Page 337

ATXMEGA256A3B-MH

Manufacturer Part Number

ATXMEGA256A3B-MH

Description

MCU AVR 256KB FLASH A3B 64-QFN

Manufacturer

Atmel

Series

AVR® XMEGAr

Specifications of ATXMEGA256A3B-MH

Core Processor

AVR

Core Size

8/16-Bit

Speed

32MHz

Connectivity

I²C, SPI, UART/USART

Peripherals

Brown-out Detect/Reset, DMA, POR, PWM, WDT

Number Of I /o

49

Program Memory Size

256KB (128K x 16)

Program Memory Type

FLASH

Eeprom Size

4K x 8

Ram Size

16K x 8

Voltage - Supply (vcc/vdd)

1.6 V ~ 3.6 V

Data Converters

A/D 16x12b; D/A 2x12b

Oscillator Type

Internal

Operating Temperature

-40°C ~ 85°C

Package / Case

64-MLF®, 64-QFN

Processor Series

ATXMEGA256x

Core

AVR8

Data Bus Width

8 bit, 16 bit

Data Ram Size

16 KB

Interface Type

I2C, SPI, USART

Maximum Clock Frequency

32 MHz

Number Of Programmable I/os

49

Number Of Timers

7

Operating Supply Voltage

1.6 V to 3.6 V

Maximum Operating Temperature

+ 85 C

Mounting Style

SMD/SMT

3rd Party Development Tools

EWAVR, EWAVR-BL

Development Tools By Supplier

ATAVRDRAGON, ATAVRISP2, ATAVRONEKIT

Minimum Operating Temperature

- 40 C

On-chip Adc

12 bit, 8 Channel

On-chip Dac

12 bit, 2 Channel

For Use With

ATAVRONEKIT - KIT AVR/AVR32 DEBUGGER/PROGRMMRATSTK600 - DEV KIT FOR AVR/AVR32770-1007 - ISP 4PORT ATMEL AVR MCU SPI/JTAG770-1004 - ISP 4PORT FOR ATMEL AVR MCU SPI

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

ATXMEGA256A3B-MU

ATXMEGA256A3B-MU

ATXMEGA256A3B-MU

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

ATXMEGA256A3B-MH

Manufacturer:

ATMEL/爱特梅尔

Quantity:

20 000

- Current page: 337 of 445

- Download datasheet (6Mb)

28. IEEE 1149.1 JTAG Boundary Scan interface

28.1

28.2

8077H–AVR–12/09

Features

Overview

•

•

•

•

•

•

The JTAG Boundary-scan interface is mainly intended for testing PCBs by using the JTAG

Boundary-scan capability. Secondary, the JTAG interface is reused to access the Program and

Debug Interface (PDI) in its optional JTAG mode.

The Boundary-scan chain has the capability of driving and observing the logic levels on I/O pins.

At system level, all ICs having JTAG capabilities are connected serially by the TDI/TDO signals

to form a long shift register. An external controller sets up the devices to drive values at their out-

put pins, and observe the input values received from other devices. The controller compares the

received data with the expected result. In this way, Boundary-scan provides a mechanism for

testing interconnections and integrity of components on Printed Circuit Boards by using the four

TAP signals only.

The IEEE 1149.1-2001 defined mandatory JTAG instructions IDCODE, BYPASS, SAMPLE/

PRELOAD, and EXTEST together with the optional CLAMP, and HIGHZ instructions can be

used for testing the Printed Circuit Board. Initial scanning of the Data Register path will show the

ID-Code of the device, since IDCODE is the default JTAG instruction. If needed, the BYPASS

instruction can be issued to make the shortest possible scan chain through the device. The

EXTEST instruction is used for sampling external pins and loading output pins with data. The

data from the output latch will be driven out on the pins as soon as the EXTEST instruction is

loaded into the JTAG IR-Register. Therefore to avoid damaging the board when issuing the

EXTEST instruction for the first time, the merged SAMPLE/PRELOAD should be used for setting

initial values to the scan ring. SAMPLE/PRELOAD is also used for taking a non-intrusive snap-

shot of the external pins during normal operation of the part. The CLAMP instruction allows

static pin values to be applied via the Boundary-scan registers while bypassing these registers in

the scan path, efficiently shortening the total length of the serial test path. Alternatively the

HIGHZ instruction can be used to place all I/O pins in an inactive drive state, while bypassing the

Boundary-scan register chain of the chip.

The AVR specific PDICOM instruction makes it possible to use the PDI data register as an inter-

face for accessing the PDI for programming and debugging. Note that the PDICOM instruction

has nothing to do with Boundary-scan testing, but represents an alternative way to access inter-

nal programming and debugging resources by using the JTAG interface. For more details on

PDI, programming and on-chip debug refer to

page

The JTAGEN Fuse must be programmed and the JTAGD bit in the MCUCR Register must be

cleared to enable the JTAG Interface and Test Access Port.

JTAG (IEEE std. 1149.1-2001 compliant) interface.

Boundary-scan capabilities according to the JTAG standard.

Full scan of all I/O pins.

Supports the mandatory SAMPLE, PRELOAD, EXTEST, and BYPASS instructions.

Supports the optional IDCODE, HIGHZ, and CLAMP instructions.

Supports the AVR specific PDICOM instruction for accessing the PDI for debugging and

programming in its optional JTAG mode.

344.

Section 29. ”Program and Debug Interface” on

XMEGA A

337

Related parts for ATXMEGA256A3B-MH

Image

Part Number

Description

Manufacturer

Datasheet

Request

R

Part Number:

Description:

DEV KIT FOR AVR/AVR32

Manufacturer:

Atmel

Datasheet:

Part Number:

Description:

INTERVAL AND WIPE/WASH WIPER CONTROL IC WITH DELAY

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

Low-Voltage Voice-Switched IC for Hands-Free Operation

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

MONOLITHIC INTEGRATED FEATUREPHONE CIRCUIT

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

AM-FM Receiver IC U4255BM-M

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

Monolithic Integrated Feature Phone Circuit

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

Multistandard Video-IF and Quasi Parallel Sound Processing

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

High-performance EE PLD

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

8-bit Flash Microcontroller

Manufacturer:

ATMEL Corporation

Datasheet:

Part Number:

Description:

2-Wire Serial EEPROM

Manufacturer:

ATMEL Corporation

Datasheet: